- ホーム

- > 洋書

Full Description

Ion plating is a hybrid vacuum coating process that combines the benefits of vacuum evaporation and sputtering. The term "ion plating" is generally applied to high energy plasma deposition methods in which the surface to be coated is subjected to a small flux of high energy ions and a much larger number of energetic neutrals before and during the deposition of the coating. This excellent handbook/reference source for ion plating covers in practical terms the characteristics of ion plating, the system needed, the process itself, the resulting coating characteristics and the many applications. Ion plating is now a major industrial process and the final chapter on the future and potential of ion plating is particularly useful.

Contents

The Characteristics of the Ion Plating ProcessSputtering; Processes Occuring Near the Cathode; Number of Ionized Particles; Ion Plating System: The Vacuum and Gas Control Unit; Evaporation Sources; Electron Beam Evaporation; The Ion Plating Process: Enhanced Ionization Sources, RF Coil Electrode; Process Control; Cleaning Metals; Deposition Rate and Thickness Monitors; Reactive Ion Plating: Nitride Coatings; Oxide Coatings; The Characteristics of Ion Plated Coatings: Adhesion; Wear; Friction; Fatigue; Applications of the Ion Plating Technique: Corrosion Protection, High Temperature Applications; Cutting Tools; Lubrication; Electrical Application.

-

- 電子書籍

- マーガレット 2022年9号

-

![はじめてのGmail入門[第5版]](../images/goods/ar2/web/eimgdata/EK-0972287.jpg)

- 電子書籍

- はじめてのGmail入門[第5版]

-

- 電子書籍

- 居酒屋あさこ~待たせずおいしいおつまみ…

-

- 電子書籍

- ガラスの仮面 10

-

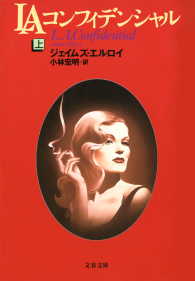

- 電子書籍

- LAコンフィデンシャル(上) 文春文庫